Crushing steel shots produces steel grit. As a result, it has the same chemical properties. The microstructure and hardness of the material are optimized thanks to a special heat treatment method. Steel grit comes in three basic varieties, each with varying degrees of hardness. Steel grit is a high-speed abrasive that can be used in recycling systems such as shot blast room and cabinets with compressed air blasting.

These products adopt the raw materials which are carefully selected, are added with the alloys with the appropriate proportion, and are transformed into steel grains or steel grits after the electric furnace smelting process. After this high-temperature process, these steel grains break into steel grit which is further classified into various categories of grit by automatic screen classification.

Steel grit’s superior hardness and confined microstructure provide maximum durability or life and impact energy transfer. It provides a very fast stripping action for many types of surface cleaning from steels and other foundry metals. Softer than aluminum oxide, but still angular in shape, steel grit will not fracture as easily making it perfect for creating an etched surface on metal. Quickly strips contaminants from steel and foundry metals. Used in wheel blast and pressure blasting systems. Steel Grit effectively produces an etching on hard metal surfaces for better adhesion of coatings including paints, enamel, and rubber.

Specifications of Steel Grit

| Grades Sizes (in mm) | G-12 1.70 G-14 1.40 G-16 1.20 G-18 1.00 G-25 0.60 G-40 0.40 G-50 0.30 |

| Packaging Size | Standard Packing of 25 Kgs |

| Packaging Type | Standard Packing |

| Country of Origin | Made in India |

| Minimum Order Quantity | 25 kilogram |

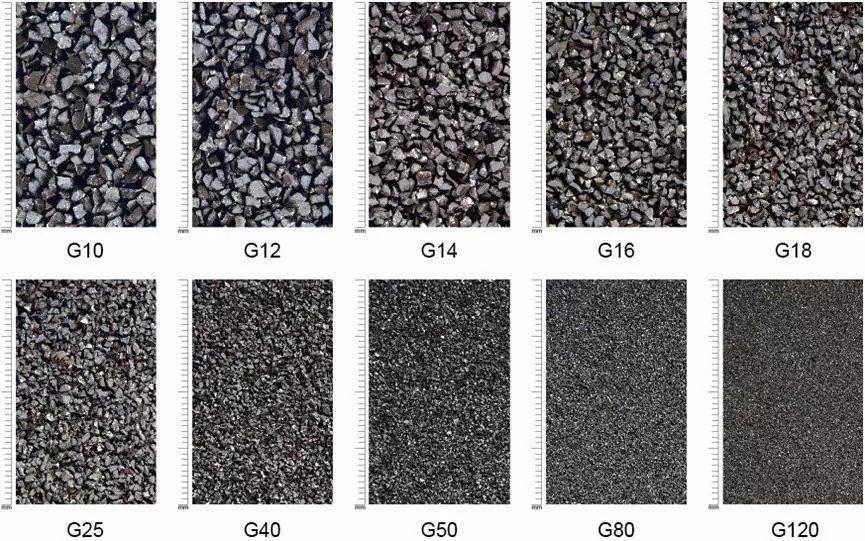

Sizes Available

|

G10 |

2.00mm |

|

G12 |

1.70mm |

|

G14 |

1.40mm |

|

G16 |

1.18mm |

|

G18 |

1.00mm |

|

G20 |

0.850mm |

|

G25 |

0.710mm |

|

G30 |

0.600mm |

|

G40 |

0.425mm |

|

G50 |

0.300mm |

|

G70 |

0.180mm |

|

G80 |

0.120mm |

Types of Steel Grit

GP Steel Grit

GP steel grit is an external form that is rounded or cylindrical and shaped with steel water, owns a fine elasticity, and the strength of a fatigue resistance as a result of fine heat treatment, applied in all aspects, special hardness steel has shot applied in strengthening a treatment.

GL Steel Grit

GL steel grit is stronger than GP steel grit, GL also loses its form is edged during a shot blasting and is particularly suited to descaling and surface preparation applications.

GH Steel Grit

GH steel grit is having a maximum hardness, and GH always remains angular in its operating mix. These abrasives are particularly effective in surface treatment processes and produce a uniform, an etched finish, GH angular grit should only be used in wheel machines where working requirements take precedence over cost price considerations. For use mainly with compressed air blasting equipment.

Steel Grit Abrasive Price

Our steel grit abrasives price is best with high quality. These smaller particles then produce a smaller blast profile on to the merchandise on the opposite hand the larger particles (the ones that have smaller G numbers) can produce a deeper blast profile. In associate addition to the depth of the blast profiles, the larger particles can show effectiveness in the removal of significant amounts of paint whereas the smaller lot of particles are going to be best suited to removing contaminants on lighter surfaces.

An additional profit connected to the steel grit is that it's the potential to be used multiple times before the necessity of replacement the grit arises. One will use mechanical blast media recovery instrumentality if you would like to recover and use the media once more. this permits the media to be used or so a hundred and fifty to two hundred times before it must get replaced with a recent blast media.

This grit is good for serving to get rid of the contaminants from the surface of the assorted products and it additionally creates a final profile for the brand new coating to stick to the foremost common uses for steel grit area unit removing of mill scale, removing totally different degrees of coatings from the surface of the product and a typical grit sizes that area unit most ordinarily used vary between G25 – G80. The larger the grits, the smaller are going to be the dimensions of the particular particle of blast media.

Steel grit is part of the steel abrasives family, which includes steel grit and steel shot. Steel shot is made up of round steel balls; nevertheless, some applications demand sharper edges, therefore steel grit is utilized.

Steel grit should be tougher than the material it is abrading because it is used as an abrasive. As a result, steel grit is often made from high carbon and high alloy steel. Steel grit is typically produced of stainless steel so that the completed product does not rust, which may happen if ordinary carbon steel was used.

Application of Steel Grit

- Flashing Removal

- Pipe Coating

- Bridge Blasting

- Epoxy Coating Preparation

- Rail Car Reconditioning

- Ship Building

- Rust Removal

- Aggressive Cleaning

- Forgings

- Non-Ferrous Castings

- Plate Preparation

- Scale Removal

- Surface Preparation

Features of Steel Grit

Steel grits are softer than aluminum oxide but have a high hardness and do not easily shatter. Steel grits are useful for aircraft and aerospace applications because of this property. Steel grits can also be used to generate a precisely etched surface on metal in preparation for the adhesion of paint, enamel, epoxy, rubber, and other types of coatings due to their angular nature.

- Sufficient high limit of durability

- High resilience

- Manufactured in accordance with the prevailing international quality standards

- Versatile

- Dimensionally accurate

Application Devices

Steel grits are mostly used with the following equipment

- Rotary barrel shot blasting machine

- Cartype shot blasting machines

- Table type shot blasting machines

- Rubber pedrail type shot blasting machine

- Roller path type shot blasting machines

- Shot peening machine

Steel Grit Manufacturer in India

Abrasives Shots is the largest Steel Grit Manufacturer in India. We also provide white aluminum oxide, cut wire shots, copper slag, steel grit, garnet sand, quartz shot, aluminum oxide, glass beads, etc for the Sand Blasting Machine. We provide a large range of products and are checked on various parameters, such as density, physical and chemical properties, microstructure, hardness, and durability. We are focused on our quality products and customer satisfaction.

We have been able to create high-quality steel grits because of our modern technology and state-of-the-art equipment, as well as our in-house experienced professional engineers, technicians, and quality controllers.

To enable us to quote for your requirement, kindly give us the following info –

1. Particle size required (You may choose from above or give your own range).

2. Packing required.

3. Quantity required with the delivery schedule.

4. Destination port.

5. Discharge rate at the destination, if in break-bulk.

6. Any other point which may impact the quote.

We can also offer ungraded material for shipments in bulk in any quantities as desired by our buyers on FOB or CNF FO basis terms.

You can reach out to us by dialing +91-9119207701 or by sending us an email at abrasivesshots@gmail.com. Contact us today!